Introduction

In the fast-evolving world of construction, innovative changes and IoT are revolutionizing various industries, including lighting. Among the notable innovations is the pre-commissioned light control system for commercial buildings, transforming our interaction with the spaces we inhabit. This article sheds light on the compelling advantages of pre-commissioned light control systems for commercial buildings, showcasing why architects and engineers in the design community are increasingly specifying and requesting them.

Table of contents

- Introduction

- Advantages of Pre-Commissioned Light Control Systems for Commercial Buildings

- 1) Simplified Installation with Energywise Solutions’ Expertise

- 2) Cost Savings: A Financial Game-Changer

- 3) Ease of Installation: Uncomplicated and Quick Setup

- 4) Enhanced User Experience: Personalization and Comfort

- 5) Unrivaled Convenience: Smooth Control and Integration

- 6) Versatility and Scalability: Adapting to Diverse Needs

- Conclusion: A Brighter Future with Pre-Commissioned Light Control Systems

- FAQs

Advantages of Pre-Commissioned Light Control Systems for Commercial Buildings

1) Simplified Installation with Energywise Solutions’ Expertise

Energywise Solutions takes the concept of hassle-free installation to a new level through its innovative approach. With the integration of factory pre-linking and pre-configuration, their self-powered, wireless lighting- and temperature-control products redefine efficiency.

This process involves the pre-linking of sensors, switches, and I/O modules to their respective controllers, meticulously labeled by zone and/or room number, and thoughtfully packaged as a cohesive unit. Furthermore, the controllers themselves are pre-configured to match the precise requirements of each individual space, all based on the valuable input provided by the customer. The result? A streamlined installation process that significantly reduces the time required for on-site job commissioning, ensuring that the benefits of these cutting-edge systems are experienced sooner and with maximum ease.

2) Cost Savings: A Financial Game-Changer

Apart from direct savings from reduced energy consumption, pre-commissioned light control systems offer economic benefits in various ways. Their intelligent design often includes predictive maintenance capabilities, alerting management to potential issues before they escalate into costly problems, thus significantly reducing maintenance expenses. Additionally, pre-configuration before installation simplifies the commissioning process, saving time and resources that would typically be spent on system setup and calibration.

3) Ease of Installation: Uncomplicated and Quick Setup

Traditional lighting control systems often involve complex installations, requiring specialized knowledge and extended time. However, pre-commissioned light control systems have a significant advantage in this regard. Being pre-configured before installation eliminates the need for complex on-site setup and programming, making the installation process much faster and simpler. Their plug-and-play nature ensures flawless performance from day one, reducing errors that could occur during the commissioning phase.

4) Enhanced User Experience: Personalization and Comfort

Another significant advantage of pre-commissioned light control systems is the enhanced user experience they deliver. These systems can be personalized to cater to individual lighting preferences, allowing users to create the ideal environment to suit their needs. The system’s intelligent design enables automatic adaptation to environmental conditions, ensuring optimal lighting conditions at all times. This blend of personalization and automatic adaptability guarantees maximum comfort and user satisfaction, enhancing the overall user experience.

5) Unrivaled Convenience: Smooth Control and Integration

Pre-commissioned light control systems provide optimal lighting conditions without the need for manual intervention. Their integration with other building systems, such as heating, ventilation, and security, ensures users can manage multiple aspects of their facilities from a single platform, significantly streamlining building operations.

6) Versatility and Scalability: Adapting to Diverse Needs

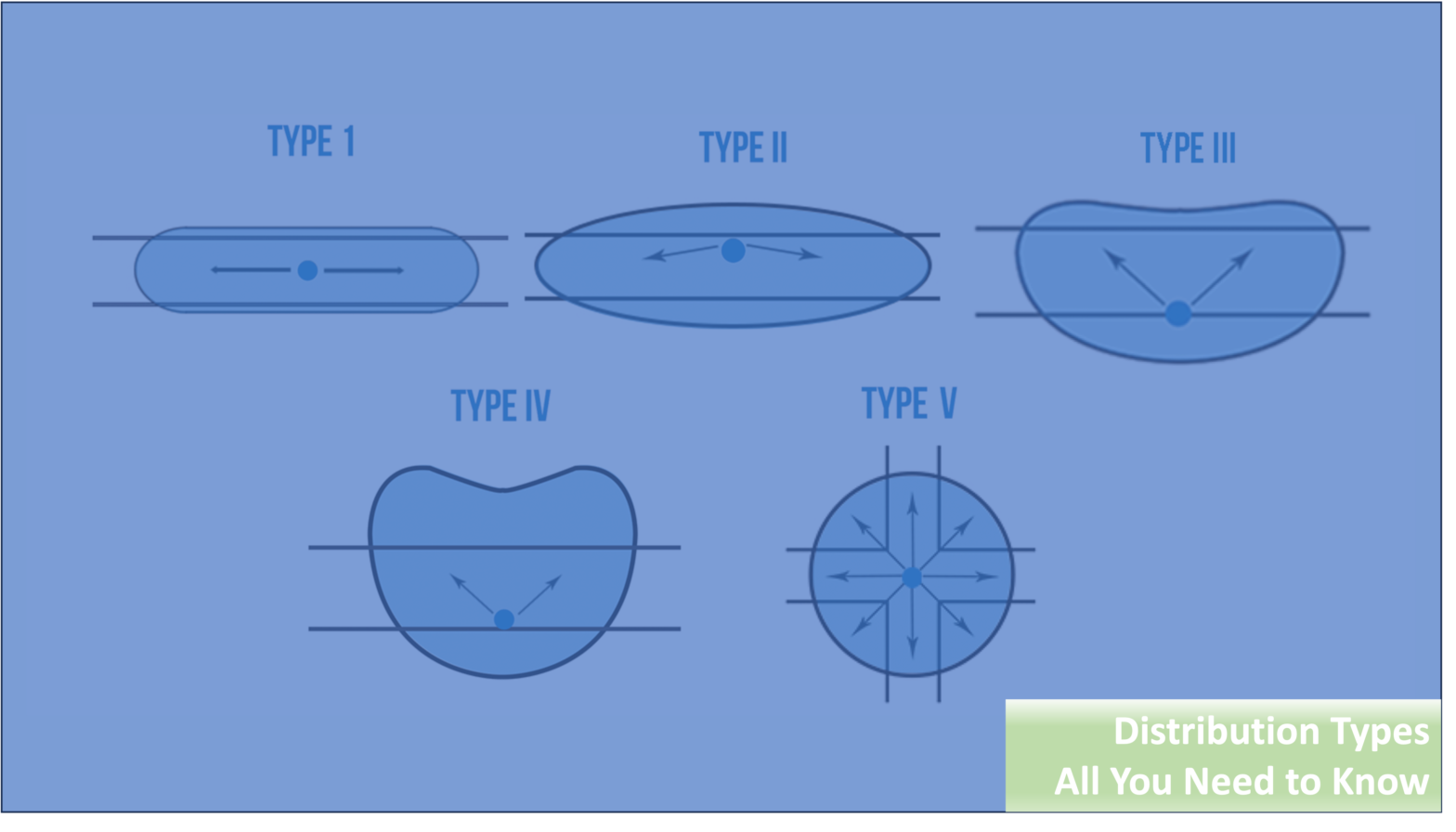

Pre-commissioned light control systems are not one-size-fits-all solutions. Instead, they offer remarkable versatility, catering to various types of commercial buildings, including office spaces, hospitality venues, educational institutions, and healthcare facilities. Their scalability makes them an ideal choice for both small renovations and large-scale building projects, offering customization to fit the specific project’s scale.

Conclusion: A Brighter Future with Pre-Commissioned Light Control Systems

In summary, pre-commissioned light control systems stand as the future of lighting, offering a myriad of advantages that set them apart from traditional solutions. Their energy efficiency, cost savings, convenience, versatility, enhanced user experience, and longevity make them increasingly appealing to modern commercial buildings. With their seamless installation process and readiness to adapt to evolving technologies, pre-commissioned light control systems pave the way towards a brighter and more sustainable future. Embracing these systems not only enhances daily experiences but also contributes positively to the environment and the economy.

FAQs

Pre-commissioning is the process of thoroughly testing and preparing a system or equipment before its final installation or deployment. In the context of lighting control systems, it ensures that all components are installed correctly, operate as intended, and are ready for the final commissioning tests.

Advantages of pre-commissioned light control systems for commercial buildings is vital for several reasons. It ensures the proper operation of the system, optimizes energy efficiency, tailors the system to user needs, assures safety, and ensures compliance with regulatory standards. It also helps identify and rectify any defects, issues, or deficiencies in the system before installation, which helps mitigate risks, reduces costly delays, and ensures that the system performs optimally when operational.

Pre-commissioning offers various benefits, such as improved system performance, energy and cost savings, risk mitigation, and enhanced user satisfaction. In addition, it optimizes integration with other systems and facilitates familiarization and training.

Pre-commissioning is typically carried out by a team of qualified and experienced technicians, engineers, or specialists, like Energywise Solutions, with expertise in the specific system or equipment being tested. They work closely with the manufacturer or supplier to ensure proper testing and preparation.

As a leading provider of lighting systems and solutions, Energywise Solutions takes a proactive approach to pre-commissioning. With a team of expert technicians and engineers, the company ensures that pre-commissioned light control systems meet the highest standards of performance and reliability.

The pre-commissioning process includes several steps, such as an initial system assessment, functional performance tests, necessary adjustments, and detailed documentation and handover. It also includes functional testing, calibration, system checks, integration testing (if applicable), performance optimization, and creating documentation and records for future reference.

No, pre-commissioning is a preparatory step that precedes commissioning. Commissioning occurs after installation and involves the final testing, verification, and validation of the entire system in its operational environment.

Absolutely! Pre-commissioned light control systems can be customized to cater to specific user requirements and preferences. Whether it’s adjusting lighting levels for different spaces or implementing personalized scheduling, these systems offer flexibility to meet diverse needs.

If issues are discovered during pre-commissioning, they are documented and addressed by the technical team. Depending on the severity of the problem, it may involve adjustments, repairs, or replacements to ensure the system meets the required standards.

Skipping pre-commissioning to save time or cost is not recommended. Although it might seem like a shortcut, it can lead to greater expenses and delays in the long run due to unforeseen problems during installation or operation.

Pre-commissioning is particularly crucial for complex systems, critical infrastructure, and projects with specific performance requirements. However, its implementation can be adapted based on the scale and nature of the project to ensure its effectiveness.

In some cases, certain pre-commissioning activities can be conducted remotely if the system or equipment supports remote access and testing. However, pre-commissioning in the factory or technician’s shop prior to distribution to the site is often necessary and preferred for a comprehensive assessment.

Stakeholders, such as project owners, facility managers, and end-users, are typically not involved in the pre-commissioning process.

Pre-commissioning ensures that the design criteria is followed by installers by conducting a comprehensive evaluation of the system against the specified design criteria before installation. Through functional tests and performance checks, any deviations from the design intent can be identified and corrected. This process guarantees that the final installation adheres to the prescribed design standards.

Yes, pre-commissioning serves as a critical quality control step to detect any deviations from the approved system design. By comparing the actual system performance during pre-commissioning with the design criteria, any discrepancies or non-compliance can be promptly identified and rectified. This thorough inspection maintains consistency between the intended design and the actual implementation, ensuring that the system goes live without any design-related hitches.